Production advantages

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers.

01

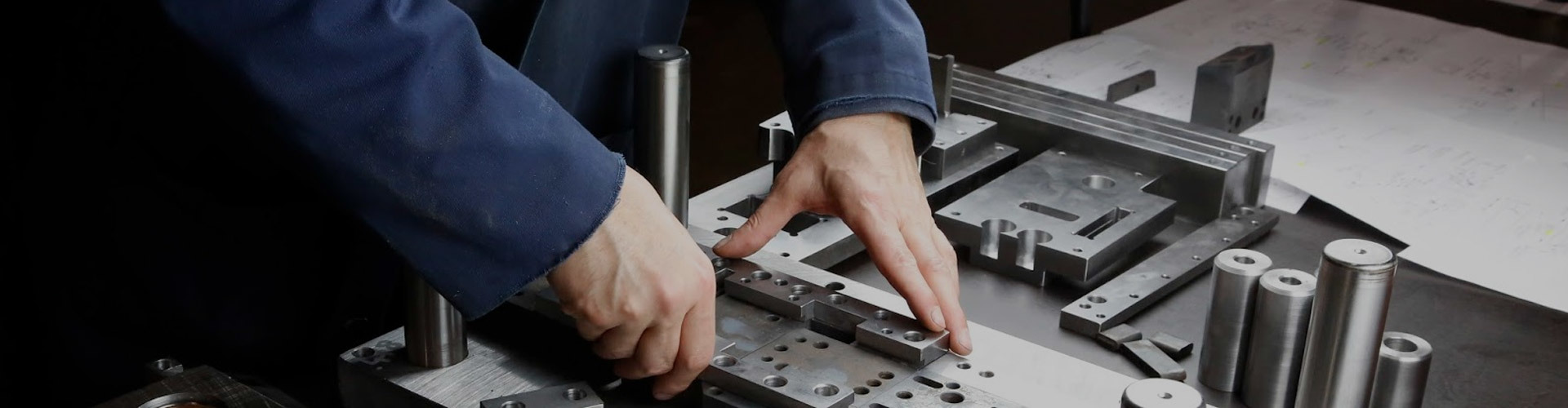

Mold development, design and manufacture

Engineering development technical team size: 30 people

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

Die precision machining department case

The CNC machining center

has two YMC430 imported from Japan, 3 Senjing from Japan, 5 Fanuc and other high precision equipment and machinery. It has a highly efficient technical team with about 15 years of experience

Slow walking wire processing center

has 7 sets of Sadiq imported from Japan, 7 sets of China Yi optical wire cutting and other high precision equipment, with a 15 years of experience and high efficiency technical team

Specular spark Machining Center

has 7 sets of SAdiq imported from Japan, 9 sets of Taiwan Taiyi brand and other high precision equipment, with a 15 years of experience and high efficiency technical team

Mold precision testing center

has imported from Germany three dimensional (Zeiss) high precision three-dimensional testing 2 sets, China two dimensional testing 2 sets, Japan imported QHQ hardness testing equipment 1 set and other high precision equipment, with a quality inspection of about 10 years of high efficiency technical team