Strictly control quality to create a model for precision mold manufacturing.

Release time:

2024/11/29

In today's rapidly changing global manufacturing industry, precision manufacturing has become an important indicator of a mold company's competitiveness. As a professional supplier of precision plastic molds in China, Dongguan Shenke Mould Co., Ltd. has gained high recognition in the industry due to its excellent technical strength and strict quality control.

In today's rapidly changing global manufacturing industry, precision manufacturing has become an important indicator of a mould company's competitiveness. As a professional supplier of precision plastic moulds in China,Dongguan Shenke Mould Co., Ltd.has won high recognition in the industry with its excellent technical strength and strict quality control.

Recently, Brother Qiang visited Shenke Mould in-depth and had an in-depth dialogue with the general manager of Shenke Mould, revealing the secrets of its success in the field of precision manufacturing.

Professional mould manufacturing and diversified product applications

Dongguan Shenke Mould Co., Ltd. is not only an experienced professional mould manufacturer but also provides one-stop services from mould design, mould flow analysis research to manufacturing and injection molding. With years of industry accumulation, the company provides high-quality mould products for various fields such as automotive parts, electronic components, medical products, telecommunications tools, household appliances, and industrial components, as well as specialized mould accessory supply services.

In the exclusive interview, the general manager shared how Shenke Mould ensures that moulds can accurately meet customer needs during the manufacturing phase by optimizing design solutions. According to the general manager, mould flow analysis is an important part of this process. By simulating the flow of materials in the mould, the company can avoid potential problems in the early design stage and customize optimal solutions for customers. In addition, Shenke Mould not only manufactures complete sets of moulds but also focuses on high-precision mould accessory production, further showcasing its diversified manufacturing capabilities.

"Our goal is to ensure that every product from our customers receives the most optimized solution from design to finished product," emphasized the general manager. This customer application-oriented brand strategy has helped Shenke Mould gain the trust of well-known enterprises such as Audi, thereby continuously enhancing Shenke Mould's influence in the field of precision manufacturing.

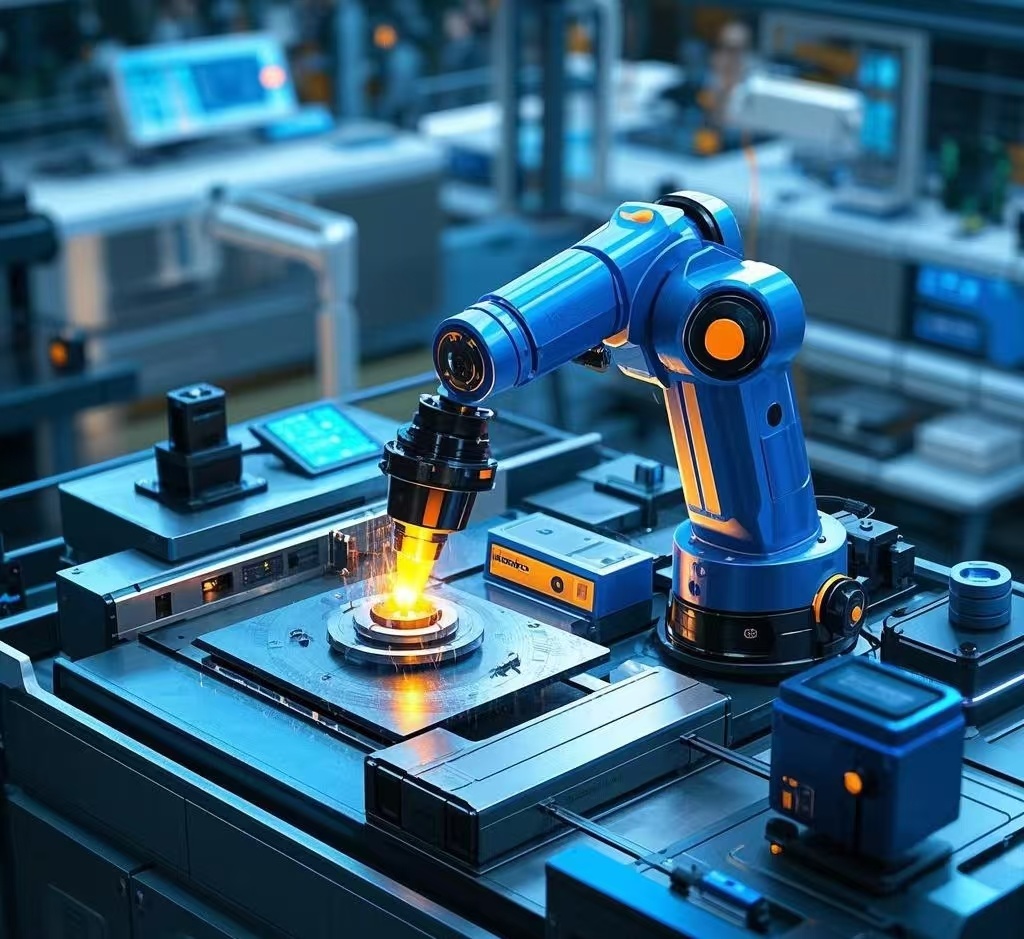

Modern factory and leading equipment ensure efficient production

Entering the modern factory of Dongguan Shenke Mould Co., Ltd. located in Dongguan City, one is greeted by a series of advanced processing equipment and highly automated production lines. The 2000 square meter production workshop not only provides ample space for mould manufacturing but is also equipped with top-notch processing equipment such as Sodick slow wire EDM machines, MAKINO V33i, MAKINO f5, FANUC copper machines, and Toshiba-180 ton injection molding machines. It is these advanced devices that ensure Shenke Mould's leading position in high precision and high efficiency within the industry.

The automation of the factory and the precision of the equipment greatly enhance production efficiency and product quality. The company has also introduced cutting-edge CAD/CAM software such as UG, CATIA, SolidWorks, and Moldflow to provide strong technical support for mould design and production. These tools enable comprehensive control from part design to mould manufacturing, ensuring that every customized requirement from customers can be flexibly responded to.

During the interview, the general manager emphasized that it is precisely the combination of modern equipment and processes that gives Shenke Mould extraordinary flexibility in complex mould design and manufacturing, thus meeting various complex processing needs and product requirements from customers while providing high-quality mould products to global clients.

Strict quality control processes and testing technologies

In manufacturing, quality is fundamental for a company to establish itself in the market. Dongguan Shenke Mould Co., Ltd. understands this well and has established a strict quality control system that closely monitors every link from design to production. The company has set up a professional quality inspection department equipped with advanced testing equipment including CMM (Coordinate Measuring Machine), Leighton two-dimensional/three-dimensional measuring devices, etc., ensuring that all moulds and parts undergo precise measurement and strict review before entering the next stage of production.

In the exclusive interview, General Manager Zhong detailed his strict QC process, which includes optimizing design solutions, testing steel hardness, checking electrodes, and assembling moulds; each step undergoes rigorous scrutiny. Especially during the component measurement phase after mould manufacturing, each cavity insert and core insert is carefully measured by the inspection department to ensure all dimensions accurately meet drawing requirements. In addition, sampling checks and dimensional reports for final products are also provided to customers to ensure transparency and quality.

The general manager stated: "We adhere to the principle that 'without quality, there is no future.' Through high-standard quality management and continuous technological innovation, we ensure that every project meets customer expectations." It is this extreme pursuit of detail that has established Shenke Mould's excellent reputation among domestic and international clients and made it a trusted partner in the industry.

Through this exclusive interview with Shenke Mould, we deeply feel its outstanding strength in precision manufacturing and its persistent pursuit of quality. From diversified mould products to modern production equipment to strict quality control systems, Shenke Mould has successfully established a high standard industry model through innovation and professionalism.

Looking ahead, Yongchengxin will continue to uphold its relentless pursuit of technology and quality while continuously improving its technology and service levels to enhance China's manufacturing influence and competitiveness in the global market. We look forward to Yongchengxin continuing to lead trends in future mould manufacturing fields and creating more brilliant chapters.

Previous article

Previous article