How to determine the injection method of the gate for plastic molds?

Release time:

2024/12/19

The injection methods for the plastic injection mold gate mainly include point gate, submarine gate, needle valve gate, and direct gate. A reliable manufacturer will consider the cost of the plastic mold. Different gate types can lead to significant differences in mold costs; hot runner gates and point gates are more expensive than ordinary submarine and direct gates.

The methods for feeding plastic injection molds mainly include point feeding, underwater feeding, needle valve feeding, and direct feeding. A reliable manufacturer will consider the cost of plastic molds. Different feeding methods can lead to significant differences in mold costs; hot runner feeding and point feeding are more expensive than ordinary underwater and direct feeding. We should choose the appropriate feeding method while ensuring the quality of plastic molds and the requirements of plastic products. Each feeding method has its own advantages and disadvantages, so what aspects should we consider when designing plastic molds? Let's take a look with Mingyang Yutong's editor.

1. Customer Requirements

Many customers have very clear requirements regarding the position and method of the feeding port. When determining the feeding method, customer requirements should be prioritized, and any necessary changes must be justified.

2. Appearance and Assembly Requirements of Plastic Products

Many plastic products have strict appearance requirements, such as some digital electronic plastic components, where the product surface must not have any defects. When choosing the feeding method and position, we must consider whether it will affect appearance and assembly.

3. Position of the Feeding Port

The position of the feeding port and the feeding method are interrelated. For example, when feeding on the product surface, we usually choose a feeding method that is easy to break and stable.

4. Cost of Plastic Molds

Different feeding ports can lead to significant differences in mold costs; hot runner feeding and point feeding are more expensive than ordinary underwater and direct feeding. We should choose an appropriate feeding method while ensuring the quality of plastic molds and the requirements of plastic products.

The above is organized and edited by Shenke Mould on how to choose a feeding method for plastic two-color mold injection. If you want to learn more about plastic two-color mold injection, please continue to follow us at Mingyang Yutong Plastic!

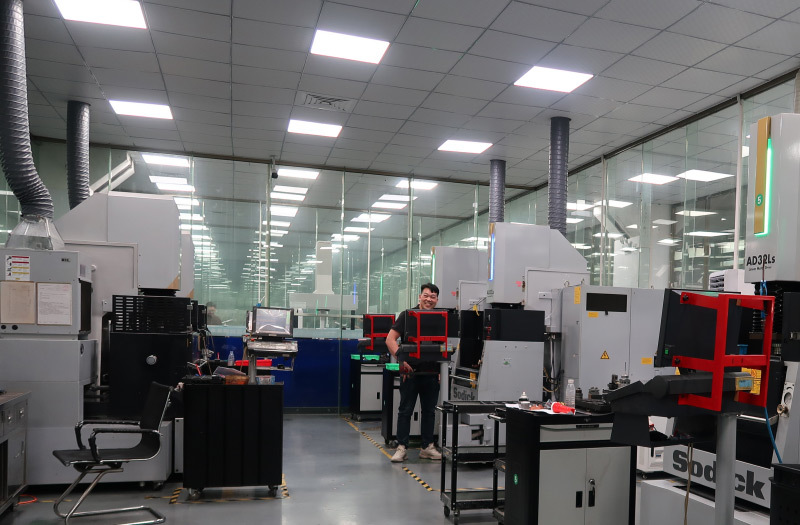

From the above content, it can be seen that good mold making is very important in terms of equipment and technology. Shenke Mould's two-color mold experts have the strength to produce high-quality molds. If you have any mold-related needs, feel free to call us for custom inquiries.

Next article

Next article