Plastic casing for medical device equipment

The plastic shell of medical device equipment is an important component of medical devices. It not only serves to protect the internal components but also relates to the overall aesthetics and user experience of the device.

Email:

The plastic shell of medical device equipment is an important component of medical devices. It not only protects the internal components but also relates to the overall aesthetics and user experience of the device. The following is a detailed analysis of the plastic shell of medical device equipment:

1. Material Selection

The choice of material for the plastic shell of medical device equipment is crucial. It must meet the special requirements of medical devices, such as corrosion resistance, high-temperature resistance, and biocompatibility. Common materials include:

ABS: ABS is a thermoplastic polymer material with high strength, good toughness, and ease of processing. Due to its high strength, corrosion resistance, and high-temperature resistance, it is often used to manufacture plastic shells for medical devices. ABS not only has good rigidity, hardness, and processing fluidity but also features high toughness, allowing it to be injection molded, extruded, or vacuum formed. Additionally, ABS is non-toxic and odorless, making it widely used in plastic shells for medical devices.

PP: PP is a high polymer with a highly crystalline structure due to its regular arrangement, allowing its melting point to reach up to 167°C. It is heat-resistant, corrosion-resistant, and does not have issues with environmental stress cracking. PP products can be sterilized with steam, which is a significant advantage. Therefore, PP is also commonly used to manufacture plastic shells for medical devices.

PVC: The main component of PVC is polyvinyl chloride polyhydroxyethylene, which is brightly colored, corrosion-resistant, and durable. However, due to the addition of toxic auxiliary materials such as plasticizers and anti-aging agents during manufacturing to enhance its heat resistance, toughness, and ductility, PVC products are generally not suitable for storing food and drugs. However, in medical devices, modified PVC can be used in conjunction with ABS to manufacture certain parts of the shell.

In addition, materials such as PTFE (a type of fluoroplastic known as the king of plastics) and TPU (which has excellent low-temperature flexibility and resistance to hydrolysis, blood coagulation, and microbial attack) are also used to manufacture specific medical device shells.

2. Design Requirements

The design of the plastic shell for medical device equipment must meet the following requirements:

Protection: The shell must effectively protect the internal circuits and components from damage caused by external factors such as moisture and dust.

Aesthetics: The design of the shell should be simple and elegant, in line with the overall style of medical devices while considering user aesthetic needs.

Ease of Cleaning: The shell should be easy to clean and disinfect to prevent cross-contamination.

Durability: The shell should have high durability to withstand wear and impact during daily use.

3. Manufacturing Process

The manufacturing process for the plastic shell of medical device equipment typically includes injection molding, extrusion molding, and vacuum forming. The choice of these processes depends on factors such as the material, shape, and size of the shell. During manufacturing, it is essential to strictly control process parameters to ensure the quality and performance of the shell.

4. Maintenance and Care

To extend the service life of the plastic shell for medical device equipment and maintain its performance, regular maintenance and care are necessary. Here are some suggestions:

Regular Cleaning: Use a soft cloth or specialized cleaner to wipe the surface of the shell to remove dust and dirt. Avoid using corrosive cleaners or sharp objects that could scratch the shell.

Avoid Impact: Prevent heavy objects from striking the shell to avoid damage or deformation.

Regular Inspection: Regularly check the integrity and fastening condition of the shell; if there are any looseness or damage, address them promptly.

In summary, the choice of materials for the plastic shell of medical device equipment, design requirements, manufacturing processes, as well as maintenance and care directly relate to the performance and service life of the equipment. Therefore, these factors should be fully considered during design and manufacturing processes to ensure that the quality and performance of the shell meet the requirements for medical devices.

Classification:

Medical injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

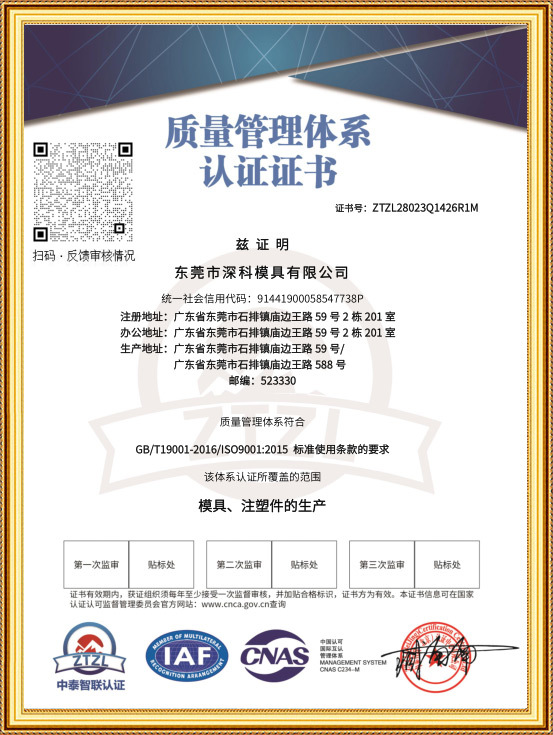

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.