Plastic bottle

Plastic bottles are packaging containers made from plastic materials, commonly made of PET, PE, PP, etc. They are lightweight, portable, sturdy, durable, have high transparency, and are resistant to chemical corrosion with stable chemical properties. Manufacturing Process: Injection Molding: Melted plastic is injected into the mold cavity, cooled, and solidified to obtain plastic products. This process is commonly used to manufacture components such as bottle caps, stoppers, and pump heads. The products produced have high precision and can create complex shapes. Applications: Food and Beverage Industry: Widely used for packaging drinking water, carbonated beverages, fruit juices, tea drinks, alcoholic beverages, cooking oil, condiments, etc., such as common PET beverage bottles and PP cooking oil bottles. Cosmetics Industry: Can be used for packaging creams, lotions, aqueous solutions, perfumes, serums, etc. Different materials and shapes of plastic bottles can meet the diverse packaging needs of cosmetic brands, such as acrylic materials commonly used for high-end cream bottles, and PETG materials used for special-shaped lotion bottles. Pharmaceutical Industry: Used for packaging medicines, health products, medical reagents, etc., requiring plastic bottles to have good sealing, stability, and hygiene to ensure the safety of drug quality. Daily Necessities Industry: Products such as shampoo, shower gel, laundry detergent, dishwashing liquid, as well as toothpaste and skincare products are often packaged in plastic bottles. Industrial Field: Can be used for packaging chemical raw materials, paints, inks, lubricants, and other industrial products. The appropriate material of plastic bottles is selected based on the characteristics of different products to ensure the safety of storage and transportation. Recycling: The recycling of plastic bottles is of great significance for environmental protection and resource conservation. Through physical recycling methods, such as cleaning, drying, and granulation processes, discarded plastic bottles can be processed into recycled plastic pellets for the manufacture of new plastic products.

Email:

Plastic bottles are packaging containers made from plastic as raw material. Common materials include PET, PE, and PP. They are lightweight, portable, sturdy, durable, have high transparency, and are resistant to chemical corrosion with stable chemical properties.

Manufacturing Process:

- Injection molding: Melted plastic is injected into the mold cavity, cooled, and solidified to obtain plastic products. This method is commonly used to manufacture components such as bottle caps, stoppers, and pump heads. The products produced have high precision and can create complex shapes.

Applications:

- Food and beverage industry: Widely used for packaging drinking water, carbonated beverages, fruit juices, tea drinks, alcoholic beverages, cooking oil, condiments, etc., such as common PET beverage bottles and PP cooking oil bottles.

- Cosmetics industry: Can be used for packaging creams, lotions, aqueous solutions, perfumes, serums, etc. Different materials and shapes of plastic bottles can meet the diverse packaging needs of cosmetic brands, such as acrylic material commonly used for high-end cream bottles, and PETG material used for uniquely shaped lotion bottles.

- Pharmaceutical industry: Used for packaging medicines, health products, medical reagents, etc., requiring plastic bottles to have good sealing, stability, and hygiene to ensure the safety of drug quality.

- Daily necessities industry: Products such as shampoo, shower gel, laundry detergent, dishwashing liquid, as well as toothpaste and skincare products are commonly packaged in plastic bottles.

- Industrial field: Can be used for packaging chemical raw materials, paints, inks, lubricants, and other industrial products. The appropriate material of plastic bottles is selected based on the characteristics of different products to ensure the safety of storage and transportation.

Recycling:

- The recycling of plastic bottles is of great significance for environmental protection and resource conservation. Through physical recycling methods, such as cleaning, drying, and pelletizing processes, discarded plastic bottles can be processed into recycled plastic pellets for the manufacture of new plastic products.

Classification:

Other injection molds

Key words:

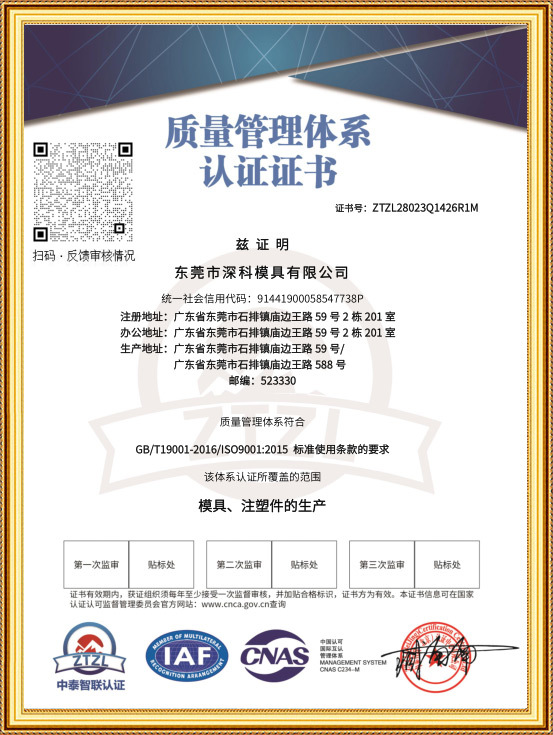

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.