Night light plastic shell

The plastic shell of the night light is an important component of the night light. It not only protects the internal circuits and bulbs but also determines the appearance and texture of the night light.

Email:

The plastic shell of the night light is an important component, which not only protects the internal circuits and bulbs but also determines the appearance and texture of the night light. Below is a detailed introduction to the plastic shell of the night light:

1. Material

The plastic shell of the night light is usually made of materials such as ABS, PC, PVC, and PP. These materials have excellent processing performance, corrosion resistance, insulation, and weather resistance, meeting the requirements for shell materials of night lights.

2. Types and Shapes

There are many types and shapes of plastic shells for night lights, commonly including the following:

Round shell: Suitable for various spherical night lights, such as moon lamps and globe lamps.

Square shell: Commonly found in minimalist style night lights with simple and smooth lines.

Animal-shaped shell: Such as cartoon animal night lights, where the shell shape corresponds to the animal image, making it cute and interesting.

Creative-shaped shell: Such as sand flow lamp shells and projection lamp shells, with unique shapes that are creative and fun.

3. Production Process

The production process of the plastic shell for night lights mainly includes injection molding, blow molding, and rotational molding. Among them, injection molding is the most commonly used production process due to its high efficiency, low cost, and strong adaptability. Blow molding and rotational molding are suitable for producing complex shapes and larger-sized night light shells.

4. Functions and Features

Protective function: The plastic shell of the night light can protect the internal circuits and bulbs from external environmental interference and damage.

Decorative role: The color, pattern, and shape of the shell can enhance the aesthetic appeal and fun of the night light, meeting consumers' aesthetic needs.

Heat dissipation performance: Some plastic shells for night lights are designed with heat dissipation holes or structures to improve heat dissipation performance and extend service life.

5. Market Supply Situation

The supply of plastic shells for night lights in the market is very sufficient, with many suppliers offering different types, materials, and shapes of shells for consumers to choose from. Consumers can find suitable plastic shells for night lights in the market based on their needs and preferences.

6. Selection Suggestions

When choosing a plastic shell for a night light, consumers should pay attention to the following points:

Material selection: Choose suitable materials based on your needs and budget. If higher transparency and gloss are required, PC material can be chosen; if better impact resistance and wear resistance are needed, ABS material can be selected.

Shape and size: Choose a suitable shape and size of the shell based on the design of the night light and usage scenarios.

Quality inspection: Before purchasing, check the quality of the shell to ensure there are no damages, deformations, or scratches.

Price comparison: Compare prices and services from different suppliers in the market to choose products with high cost-performance ratio.

In summary, as an important component of night lights, plastic shells have various functions and features. When choosing, consumers should consider their needs and budget comprehensively to ensure they purchase suitable products.

Classification:

Household appliance injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

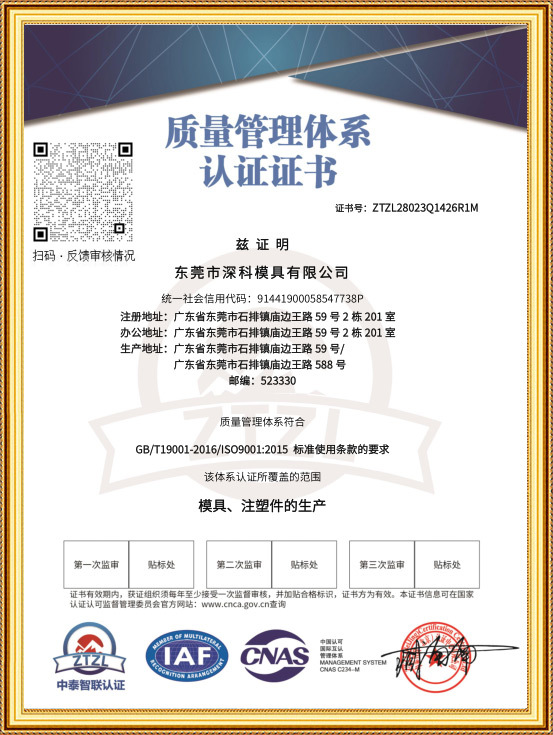

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.