Router plastic casing

In the field of network devices, routers serve as a crucial hub for network connections, making the design and quality of their plastic casing essential. This router's plastic casing is made from high-strength, high-toughness engineering plastics, crafted through a meticulous injection molding process. The surface of the casing features a unique matte finish, which not only provides a delicate and comfortable touch but also effectively prevents fingerprint residue and scratches, keeping its appearance clean and aesthetically pleasing. From a structural design perspective, it fully considers the internal heat dissipation needs of the router, carefully laying out numerous ventilation holes to ensure that the device maintains a stable operating temperature even during prolonged use, thus avoiding performance degradation due to overheating. Additionally, its compact and reasonable structural design ensures the secure installation of internal electronic components while providing users with convenient operational interfaces, making it easy to connect network cables or configure the device. This plastic casing also boasts excellent electromagnetic shielding performance, effectively reducing electromagnetic interference from internal circuits to the external environment, while also protecting the router's operation from external electromagnetic signals, ensuring stable transmission of network signals. It is not only a sturdy armor for the router but also a strong guarantee for stable and smooth networking, creating an efficient and stable network environment for you.

Email:

In the field of network devices, routers serve as a key hub for network connections, making the design and quality of their plastic casing crucial. This router's plastic casing is made from high-strength, high-toughness engineering plastics, crafted through a meticulous injection molding process. The surface of the casing features a unique matte finish, which not only provides a delicate and comfortable touch but also effectively prevents fingerprint residue and scratches, keeping its appearance clean and aesthetically pleasing.

From a structural design perspective, it fully considers the internal heat dissipation needs of the router, carefully laying out numerous ventilation holes to ensure that the device can maintain a stable operating temperature even during prolonged use, avoiding performance degradation due to overheating. At the same time, its compact and reasonable structural design ensures the secure installation of internal electronic components while providing users with convenient operation interfaces, making it easy to connect network cables or configure the device.

This plastic casing also features excellent electromagnetic shielding performance, effectively reducing electromagnetic interference from internal circuits to the external environment, while resisting external electromagnetic signals that could affect the router's operation, ensuring stable transmission of network signals. It is not only a sturdy armor for the router but also a strong guarantee for stable and smooth networking, creating an efficient and stable network environment for you.

Classification:

Household appliance injection molds

Key words:

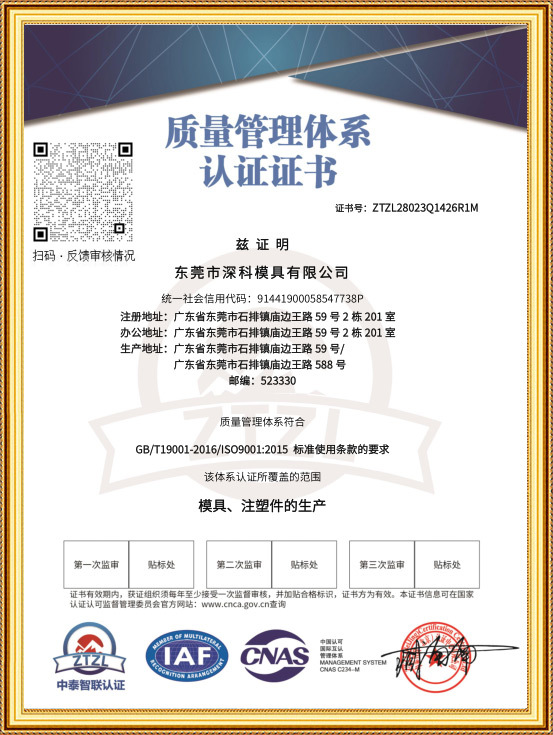

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.