Headphone plastic accessories

Our headphone plastic accessories include a range of products such as ear tips, ear caps, headphone control housings, and storage cases, providing comprehensive support for your headphone experience. These accessories are made from environmentally friendly, high-quality plastic materials, offering good flexibility and wear resistance. For instance, the ear tips and ear caps are soft and skin-friendly, fitting snugly in the ear canal, ensuring comfortable wear while effectively enhancing sound sealing and sound quality purity. The designs come in various sizes to meet the needs of different users, ensuring that everyone can find the most comfortable fit for themselves. The headphone control housing is not only elegantly designed and easy to operate but also features excellent drop resistance, effectively protecting the internal electronic components and extending the lifespan of the control. The storage case is sturdy and durable, with a special cushioning design inside, providing a safe and reliable storage space for headphones, preventing damage from compression during transport or daily storage. Whether for home use or on-the-go, these accessories offer thoughtful protection and a convenient user experience for your headphones. Additionally, our plastic accessories come in a variety of colors, allowing them to match different styles of headphones, fulfilling functional needs while showcasing unique personality.

Email:

Classification:

3C electronic headphone shell

Key words:

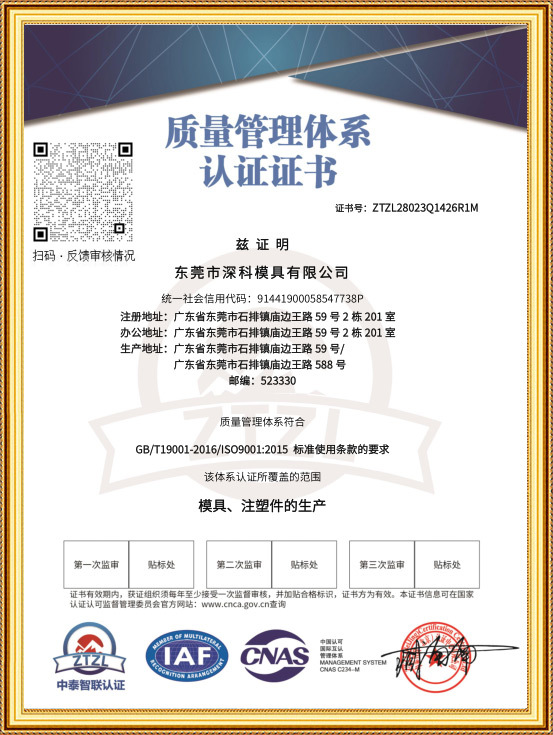

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.