Robot vacuum cleaner shell

The shell of the robotic vacuum cleaner is an indispensable component of the robotic vacuum cleaner. It not only determines the appearance and texture of the robot but also relates to its durability, protection, and production costs, among other aspects.

Email:

The shell of the robotic vacuum cleaner is an indispensable and important component. It not only determines the appearance and texture of the robot but also relates to its durability, protection, and production costs among other aspects.

The following is a detailed introduction to the shell of the robotic vacuum cleaner:

1. Material Selection

The shell of the robotic vacuum cleaner is mostly made of plastic, as plastic is low-cost, lightweight, waterproof, moisture-proof, and corrosion-resistant, making it very suitable for consumer-grade robotic vacuum cleaners. In addition, plastic shells are easy to process and shape, meeting the diverse design needs of robotic vacuum cleaners.

2. Appearance Design

The appearance design of the robotic vacuum cleaner shell usually emphasizes a combination of practicality and aesthetics. They typically adopt round or square designs, are compact in size, and are easy to move flexibly around the home. The surface of the shell is often treated to be smooth, which not only enhances the product's texture but also makes cleaning more convenient. Additionally, the shell will have brand logos, model information, and operating instructions printed on it for user identification and use.

3. Functional Features

Protection of Internal Components: The shell of the robotic vacuum cleaner effectively protects key components such as motors, sensors, and batteries from external damage like impacts and compression.

Heat Dissipation Performance: Some high-end robotic vacuum cleaner shells are designed specifically to improve heat dissipation performance, ensuring that the machine can operate stably during long periods of work.

Waterproof and Moisture-Proof: The shells of robotic vacuum cleaners typically feature waterproof and moisture-proof designs to prevent moisture from entering the machine and causing damage. This is particularly important for robotic vacuum cleaners used in humid environments like kitchens and bathrooms.

4. Production Costs and Environmental Protection

The production cost of robotic vacuum cleaner shells is relatively low due to the widespread availability of plastic materials and efficient processing technologies. However, with increasing environmental awareness, more and more manufacturers are beginning to focus on the environmental friendliness of shell materials. They are starting to use biodegradable plastics and other eco-friendly materials to reduce environmental impact. At the same time, they are also implementing energy-saving and emission-reduction measures during production to lower energy consumption and emissions.

5. Maintenance and Care

To extend the lifespan of the robotic vacuum cleaner shell and maintain its aesthetic appeal, users are advised to clean and maintain it regularly. A soft damp cloth can be used to wipe the surface of the shell, avoiding hard objects or corrosive cleaners that may scratch or damage it. Additionally, care should be taken to avoid exposing the robotic vacuum cleaner to direct sunlight or high-temperature environments to prevent aging or deformation of the shell.

6. Market Applications and Trends

Robotic vacuum cleaner shell products have broad application prospects in the market. As consumer demand for smart home products continues to increase, the market size for robotic vacuum cleaners is also expanding. Meanwhile, with continuous technological advancements and cost reductions, the design and production of robotic vacuum cleaner shells will become more diverse and personalized. In the future, the application of eco-friendly materials such as biodegradable plastics will become more widespread, while intelligence and interactivity in shells will also become new development trends.

In summary, robotic vacuum cleaner shell products have significant advantages and development prospects in terms of material selection, appearance design, functional features, production costs and environmental protection, maintenance and care, as well as market applications and trends.

Classification:

Household appliance injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

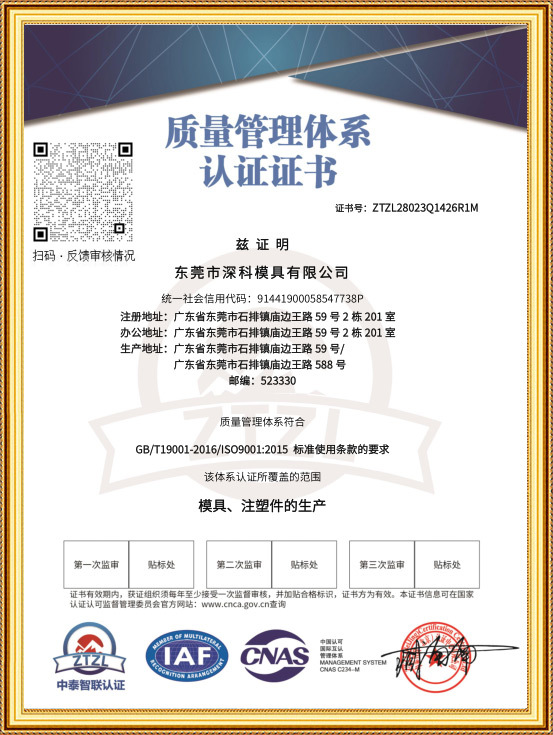

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.