mouse shell

The mouse shell is an important component of the mouse, not only affecting its appearance and feel but also relating to the durability and user experience of the mouse.

Email:

The mouse shell is an important component of the mouse, not only affecting its appearance and feel but also relating to its durability and user experience.

The following is a detailed introduction to mouse shell products:

1. Main Materials

ABS Plastic: A commonly used engineering plastic material that has high toughness, wear resistance, impact resistance, and thermal stability. ABS plastic is suitable for making sturdy and durable mouse shells and can be produced in various colors and textures to meet different user needs. However, the manufacturing process of ABS material is relatively complex, and the cost is higher.

PC Plastic: A material with high strength, high toughness, and high transparency, featuring impact resistance, aging resistance, and flame retardancy. Due to its high transparency, PC plastic is often used to make aesthetically pleasing gaming mouse shells. However, the manufacturing process of PC material is complex, and the cost is also relatively high.

Metal: Typically made from materials such as aluminum alloy, stainless steel, or titanium alloy, characterized by durability, corrosion resistance, and a rich texture. Metal mouse shells often feature eye-catching designs like RGB lighting effects, suitable for users who enjoy personalization.

Wood: A natural and environmentally friendly material commonly used to make handmade or craft mice. Wooden mouse shells have a warm texture and rich feel, and the variety of wood grains and colors can provide users with different visual enjoyment.

PVC: Good elasticity, simple manufacturing process, and low cost make it suitable for the low-end market. However, it has poor anti-static properties, easily generating static friction that can accumulate dust during use, affecting the mouse's lifespan.

PP: Lightweight with good high-temperature resistance, it can be used in high-temperature environments for mice. However, it is too soft and prone to deformation.

TPU: A relatively new material for mouse shells in recent years that has strong drop resistance, simple production processes, and low cost. It feels comfortable and is slightly softer than ABS material mouse shells.

2. Appearance Design

The appearance design of mouse shells is diverse, commonly categorized into the following types:

Skin-like Material: The surface has a skin-like touch with excellent hand feel. It is usually found in black and gray colors and is also known as rubber paint.

Frosted Material: This makes originally smooth surfaces rougher so that light reflects off the surface in a diffuse manner. It does not show obvious pressing marks, is durable, and is very popular among users.

Mirror Material: High flatness and smoothness on the surface but easily collects fingerprints, often jokingly referred to as a 'fingerprint collector.'

In addition, the design of mouse shells incorporates ergonomic principles, lightweight features, and a sense of future technology to meet different user needs.

3. Functional Features

Protecting Internal Components: The mouse shell effectively protects internal components such as circuit boards and sensors from external damage like impacts or compression.

Enhancing Hand Feel: Different materials for mouse shells provide different tactile sensations; users can choose materials and designs that suit their preferences.

Increasing Aesthetic Appeal: The diverse appearance designs of mouse shells can enhance aesthetics through colors, patterns, lighting effects, etc., improving users' aesthetic experience.

4. Maintenance and Care

To extend the lifespan of the mouse shell and maintain its aesthetic appeal, it is recommended that users regularly clean and maintain it. A soft damp cloth can be used to wipe the surface of the shell; avoid using hard objects or corrosive cleaners to prevent scratches or damage to the shell. Additionally, care should be taken to avoid exposing the mouse to direct sunlight or high-temperature environments to prevent aging or deformation of the shell.

In summary, mouse shell products come in various materials and appearance design options with rich functional features. Users should consider their needs and budget comprehensively when purchasing to choose the most suitable product.

Classification:

Other injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

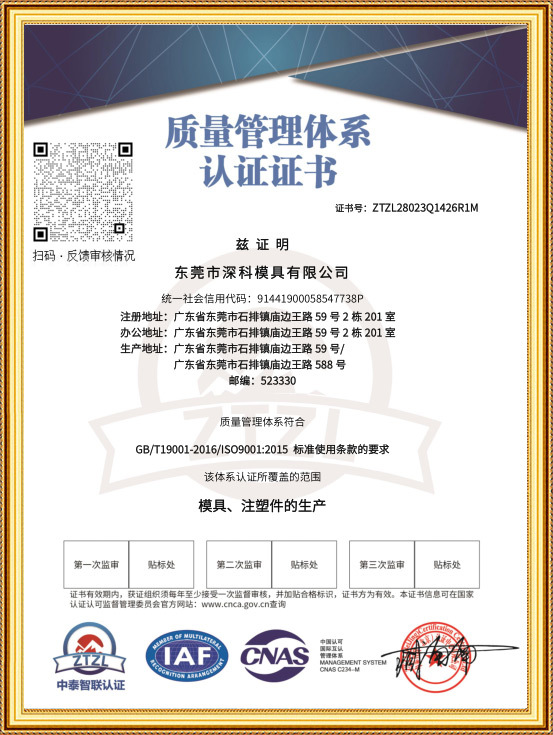

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.