Plastic shell of the bedside touch lamp

The plastic shell of the bedside touch lamp is an important component of the touch lamp. It mainly serves to protect the internal circuit, provide the tactile feel for the touch switch, and enhance aesthetic decoration.

Email:

The plastic shell of the bedside touch lamp is an important component of the touch lamp. It mainly serves to protect the internal circuits, provide a tactile feel for the touch switch, and enhance aesthetic decoration. Below is a detailed analysis of the plastic shell of the bedside touch lamp.

1. Material

The plastic shell of the bedside touch lamp is usually made of materials such as polycarbonate (PC) and polymethyl methacrylate (PMMA). These materials have excellent light transmission, heat resistance, impact resistance, and flame retardancy, effectively protecting the internal circuits and components while providing a clear tactile feel for the touch switch.

2. Structural Features

Touch Sensing Area: The plastic shell has a touch sensing area where users can control the lamp's switch and brightness adjustment by touching this area. The design of the touch sensing area is usually simple and elegant, making it easy to operate.

Heat Dissipation Holes: To dissipate heat generated by the internal circuits, the plastic shell typically has heat dissipation holes. These holes can effectively reduce the operating temperature of the lamp and extend its lifespan.

Fixed Structure: The plastic shell is connected to the lamp's base and internal circuits through screws or other fixing methods, ensuring the stability and safety of the shell.

3. Aesthetics

The design of the plastic shell of the bedside touch lamp usually considers aesthetics to meet users' aesthetic needs. The color, shape, and texture of the shell can be selected according to users' preferences and home styles. Some high-end touch lamps also adopt unique appearance designs, such as streamlined or geometric shapes, to enhance overall aesthetics.

4. Maintenance and Care

To maintain the good performance of the plastic shell of the bedside touch lamp and extend its lifespan, regular maintenance and care are required. Here are some suggestions:

Clean the Shell: Regularly wipe the shell with a soft cloth to remove dust and dirt. Avoid using corrosive cleaners or sharp objects to scratch the shell to prevent damage to its surface.

Check Touch Sensing Area: Regularly check the sensitivity and accuracy of the touch sensing area; if there are any abnormalities, contact maintenance personnel for handling.

Avoid Impact: Avoid heavy objects from hitting the shell to prevent damage or deformation.

In summary, the plastic shell of the bedside touch lamp plays an important role in touch lamps. Its material, structural features, aesthetics, as well as maintenance and care directly relate to the performance and lifespan of the touch lamp. Therefore, when selecting and using a touch lamp, attention should be paid to the quality and performance of its shell.

Classification:

Household appliance injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

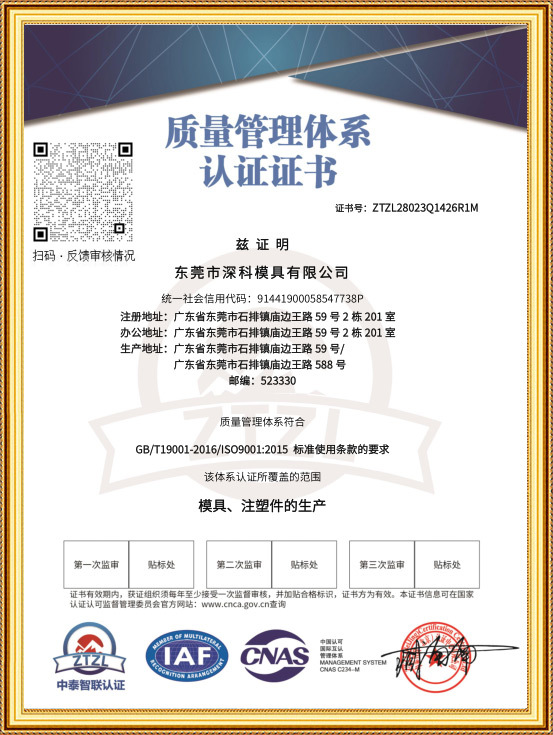

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.