Robot-shaped speaker shell

The design of the robot-shaped speaker shell integrates digital, anime, and futuristic sci-fi elements, aiming to provide users with a unique visual and auditory experience.

Email:

The design of the robot-shaped speaker shell integrates digital, two-dimensional, and futuristic sci-fi elements, aiming to provide users with a unique visual and auditory experience. Below is a detailed analysis of the robot-shaped speaker shell.

1. Material Selection

The materials used for the robot-shaped speaker shell are diverse, commonly including metal, plastic, and composite materials.

Metal Material: The metal shell is sturdy and durable, with good heat insulation, effectively protecting the internal components of the speaker. At the same time, the metal material gives the speaker a sense of futurism and technology. Common metal materials include aluminum alloy and steel plates. For example, some robot-shaped speakers use matte metal material.

The appearance resembles being covered with a thick layer of metal armor, not only appearing 'hardcore' but also avoiding a cheap plastic feel.

Plastic Material: Plastic is one of the commonly used materials for making speaker shells, with advantages such as low cost, strong moldability, and lightweight. Common plastic materials include ABS, PC, and PP. Robot-shaped speakers with plastic shells usually offer a richer variety of colors and shapes.

Composite Materials: Composite materials are made from a mixture of various materials, featuring diversity that can achieve a combination of multiple characteristics such as sturdiness, lightweight, and UV resistance. Common composite materials include carbon fiber and fiberglass. Speaker shells made from these materials are not only sturdy and durable but also exhibit excellent sound quality performance.

2. Design Features

The design features of the robot-shaped speaker shell are mainly reflected in the following aspects:

Bionic Design: The robot-shaped speaker shell typically adopts bionic design, mimicking the form and structure of robots. This design not only gives the speaker a unique appearance but also increases its fun and interactivity. For example, some speakers have mechanical legs that can be freely adjusted, with movable joints that can easily achieve the most stable three-legged stance and can extend and retract for easy portability.

Dynamic LED Ambient Lighting Effects: Many robot-shaped speaker shells are also equipped with dynamic LED ambient lighting effects. When playing music, the LED lighting effects change with the rhythm of the music, making the speaker seem alive. This design not only enhances the visual appeal of the speaker but also improves users' auditory and visual experience.

Integrated Design: The robot-shaped speaker shell usually adopts an integrated design that cleverly incorporates volume control, power buttons, and other control keys into the shell. This design not only makes the appearance of the speaker more simple and elegant but also facilitates user operation.

3. Manufacturing Process

The manufacturing process of the robot-shaped speaker shell typically includes injection molding, extrusion molding, metal processing, etc. The choice of these processes depends on factors such as material, shape, and size of the shell. During manufacturing, it is necessary to strictly control process parameters to ensure the quality and performance of the shell.

4. Maintenance and Care

To extend the lifespan of the robot-shaped speaker shell and maintain its performance, regular maintenance and care are required. Here are some suggestions:

Regular Cleaning: Use a soft cloth or specialized cleaner to wipe the surface of the shell to remove dust and dirt. Avoid using corrosive cleaners or sharp objects to scratch the shell.

Avoid Impact: Avoid heavy objects striking the shell to prevent damage or deformation.

Avoid High Temperatures: Avoid placing the speaker in high-temperature environments for extended periods to prevent deformation or fading of the shell.

Regular Inspection: Regularly check the integrity and fastening condition of the shell; if there is looseness or damage, it should be addressed promptly.

In summary, the choice of materials for the robot-shaped speaker shell, design features, manufacturing processes, as well as maintenance and care all directly relate to the performance and lifespan of the speaker. These factors should be fully considered during design and manufacturing to ensure that the quality and performance meet user needs.

Classification:

High precision injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

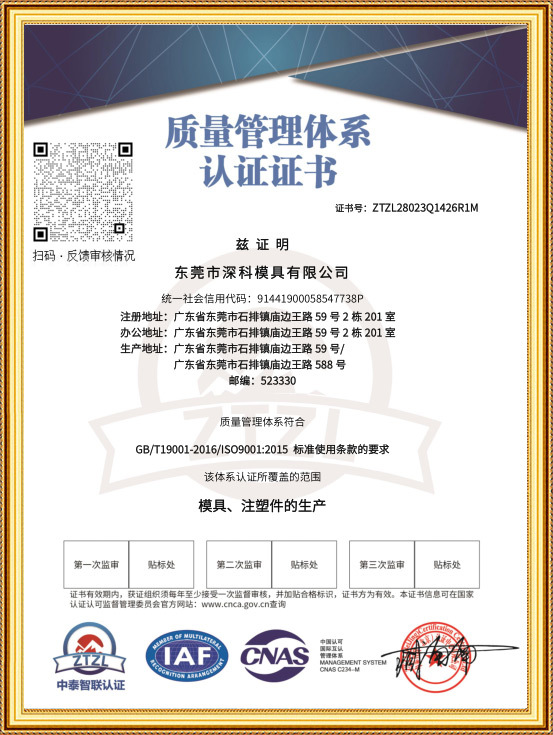

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.