Wrist blood pressure monitor with plastic casing for home use

The wrist-type home blood pressure monitor with a plastic shell is an important component of the blood pressure monitor. It not only serves to protect the internal mechanical or electronic parts but also affects the overall appearance and user experience of the blood pressure monitor.

Email:

The plastic casing of the wrist-type home blood pressure monitor is an important component of the blood pressure monitor. It not only protects the internal mechanical or electronic parts but also affects the overall appearance and user experience of the blood pressure monitor. Below is a detailed analysis of the plastic casing of the wrist-type home blood pressure monitor:

1. Material Selection

The plastic casing of the wrist-type home blood pressure monitor is usually made of ABS plastic. ABS plastic is a polymer material synthesized from three chemical monomers: acrylonitrile, butadiene, and styrene. It has high strength, thermal stability, chemical stability, toughness, impact resistance, as well as ease of processing and high gloss. These characteristics make ABS plastic an ideal material for making blood pressure monitor casings.

2. Design Requirements

Size and Weight: The size and weight of the plastic casing for the wrist-type home blood pressure monitor need to be moderate for easy carrying and use by users. Generally, the size of the casing is designed according to the internal structure and functional requirements of the blood pressure monitor.

Appearance and Texture: The appearance of the casing needs to be aesthetically pleasing and meet the aesthetic standards for household products. At the same time, the texture of the casing should also be comfortable to enhance the user's experience.

Durability: The casing needs to have a certain level of durability to withstand wear and collisions during daily use, ensuring the long-term stable operation of the blood pressure monitor.

Environmental Requirements: The materials used for the casing need to meet environmental requirements, such as RoHS and other environmental standards, to ensure the product's environmental friendliness and safety.

3. Production Process

The production process for the plastic casing of the wrist-type home blood pressure monitor typically includes injection molding and surface treatment.

Injection Molding: ABS plastic pellets are heated and melted before being injected into molds, where they cool and solidify to form the casing. Injection molding has advantages such as high production efficiency, low cost, and capability for mass production.

Surface Treatment: The surface of the casing can undergo processes such as spraying or electroplating to enhance its aesthetics and durability. Additionally, techniques like silk screening or laser engraving can be applied to add product identification or decorative patterns.

4. Market Supply Situation

Currently, there are several suppliers in the market offering custom manufacturing services for plastic casings for wrist-type home blood pressure monitors. These suppliers typically have rich production experience and advanced manufacturing equipment, capable of providing high-quality casing products based on customer needs. Meanwhile, with continuous advancements in medical technology and increasing consumer health demands, market demand for plastic casings for wrist-type home blood pressure monitors is also growing.

5. Precautions

Choose Reputable Suppliers: When purchasing plastic casings for wrist-type home blood pressure monitors, it is important to select suppliers with production qualifications and good reputations to ensure product quality and safety.

Pay Attention to Material Environmental Friendliness: The materials used for the casing need to comply with environmental requirements to avoid harm to human health and the environment.

Focus on Detail Design: The detailed design of the casing, such as button layout and display screen size, should conform to ergonomic principles to improve user experience.

In summary, the plastic casing of the wrist-type home blood pressure monitor is an important component of the device. Its material selection, design requirements, production processes, and market supply situation all need to be strictly controlled. Additionally, during use, attention should be paid to choosing reputable suppliers, ensuring material environmental friendliness, and focusing on detail design.

Classification:

Medical injection molds

Key words:

Household Appliances

Auto Parts

Medical Equipment

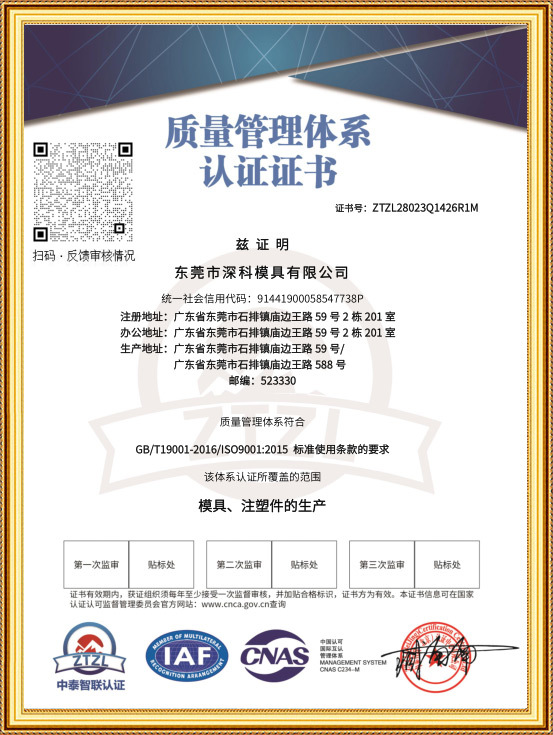

Deep branch in dongguan mould

Integration of mold manufacturing and molding production

ADVANTAGES

Development team adhering to the "customer first" service consciousness, relying on a strong professional knowledge and high quality expert team will develop its own position to provide customers with injection molding, mold development, customized one-stop service, meet customer's various customization development demand of professional team, to provide comprehensive solutions to the customers

01

Mold development, design and manufacture

Engineering development technical team size: 30 people.

02

Advanced modern precision mold equipment

62 high precision mold production equipment, the scale of 80 people.

03

Injection molding production

94 sets of injection molding equipment and 240 production personnel.

04

Product high quality testing equipment

Systematic quality management team of 30 people, advanced testing equipment: physical tester, life tester, high precision inspection size tester, etc

STANDARDIZED PROCESSING FLOW

Relying on strong professional knowledge and a high-quality expert team, we provide customers with customized one-stop services for injection molding and mold development

Demand Communication

01

feasibility analysis

02

mold design

03

Customer Confirmation

04

Mold manufacturing

05

Sample delivery

06

Internal optimization

07

Sample delivery

08

Customer Confirmation

09

Mass production

10

After-sales tracking

11

MORE PRODUCTS

PRODUCT CONSULTING

* Note: Please fill in the information accurately so as to facilitate smooth communication. We will contact you as soon as possible.